- Develop a documented ladder logic program to implement the motor control software#

- Develop a documented ladder logic program to implement the motor control download#

- Develop a documented ladder logic program to implement the motor control free#

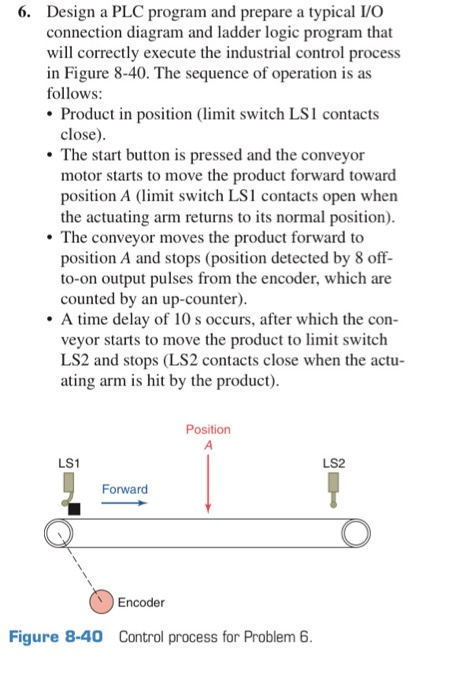

PLC manufacturers use different memory address allocation so the input output allocations used here are arbitrary address. Motor Control Ladder Diagramįirst up let’s list the required inputs and outputs for our motor control ladder diagram. Now that we’ve grasped the concept of the fail safe stop input let’s move on to the motor control ladder logic programming example. WIRE THE MOTOR STOP SIGNALS NORMALLY CLOSED AND USE A NORMALLY OPEN SYMBOLS IN THE PLC. So for any PLC input that is intended to stop the motor we need to.… So if there is no change in state, we cannot tell the motor to stop in our ladder logic program. It stays FALSE, even if the stop button is pressed, because there is an open circuit in the connection to the PLC input. However, if we wire the stop PLC inputs as normally open (NO) and a failure occurs then the state of the PLC input does not change. Wiring the stop push button normally closed (NC) is done because when a failure occurs in the PLC input circuit it will, more often than not, lead to an open circuit which changes the state of the PLC input from TRUE to FALSE. The most common failures are wire break, device failure or PLC input failure. In fact the rule of thumb is that any device that is required to stop the motor should be wired normally closed (NC), to make it “fail safe”. If Output Y is FALSE then it stays FALSE…. When both Input A and Input B are FALSE then the state of Output Y does not change. Remember Allen Bradley PLC’s use Latch and Unlatch symbols. Then you need one timer that counts down to zero. We'll call the timers for the motors, ondelay1, ondelay2 etc. You need one timer for each motor, an on-delay. Fully understanding the logic before starting to program can save you time and frustration. Let’s start with the Set (Latch) and Reset (Unlatch) logic. Develop a logical sequence of operation: Delay Starting 7 Motors.

Ladder Logic Latch with SET & RESET Symbols A great example of a device that can provide a momentary pulse to a PLC input is a push button. The inputs that set and reset the latch are usually momentary pulses. Latching in a PLC requires at least one input to set the latch (Input A), one input to reset the latch (Input B) and one output to store the latch state (Output Y).

Sometimes it just comes to personal preference. Simple applications requiring a latch are well suited to use latching logic.īut when it comes to more complex applications the use of Set (Latch) and Reset (Unlatch) symbols may be required. The disadvantage is that there is some inflexibility in programming because latching logic requires all the symbols to be on the same rung and may even overflow to the next rung. The advantage of latching logic is that troubleshooting is easier because the symbols used are all in the same rung. Quite often hold in logic is referred to as hold in logic. The disadvantage is that debugging can become more difficult because the Set (Latch) and Reset (Unlatch) symbols may be scattered throughout the program. Advantages include flexibility in programming because the Set (Latch) and Reset (Unlatch) symbols do not need to be in the same rung. These instructions simulate the function of an electromechanical latching relay.

In an Allen Bradley PLC they are called Latch and Unlatch instructions. When we use the term latching in a PLC it refers to changing the state of an output to TRUE, holding the state of that output TRUE until certain conditions occur, then returning the state of the output back to FASLE. Latching is one of the most important pieces of ladder logic programming that you’ll ever use. Let’s take a look at some very simple, but extremely important ladder logic programming examples… Latching in a PLC So by creating ladder logic programming examples we can speed up or overall programming time.Ĭonstructing a program is then a simple matter of grabbing the appropriate ladder logic programming examples and connecting them in an orderly fashion.

Develop a documented ladder logic program to implement the motor control download#

Download vBuilder to see for yourself.Experience tells us that once a piece of ladder logic is created that accomplished a specific task it can be re-used in other areas of the program and in other applications as well. True subroutines with multiple-instances.Backgound tasks (PID, Ramp, Counter, Filter, Motion.).Really powerful, flexible and easy to use.That includes the packages from the industry titans, that will cost you hundreds to thousands of euros.

Develop a documented ladder logic program to implement the motor control software#

VBuilder is the most powerful, flexible and easy to use graphical program development software available in the industry.

Develop a documented ladder logic program to implement the motor control free#

ACE PLCs can be custom programmed for your application’s requirements, using vBuilder application that is distributed free of charge.

0 kommentar(er)

0 kommentar(er)